The automotive sector in North Macedonia is experiencing dynamic development and growing importance in the national economy. A stable government framework, a cost-competitive environment, a strong technical skill base, free trade access to Europe, and ongoing infrastructure development have positioned North Macedonia as a prime investment destination. Additionally, a well-established local supplier base and its continuous expansion are creating opportunities for supply chain linkages and local business cooperation.

North Macedonia has a long history in the automotive industry, dating back to the Yugoslav period when local factories supplied the Serbian automotive producer Zastava. Over time, the country’s manufacturing sector became increasingly specialized, fostering the emergence of numerous automotive component producers. High-quality production, compliant with automotive standards TS 16949 and ISO 9001, ensures that the sector remains export-oriented. The country’s automotive components industry is experiencing significant growth, driven by strategic government policies, geographical advantages, and a cost-competitive market environment.

North Macedonia is particularly suited for the production of high-value, weight-sensitive, and labor-intensive automotive components, including:

In recent years, North Macedonia has been developing into an emerging hub for automotive components and bus manufacturing.

The country currently has manufacturing capabilities and growth potential in the following automotive component systems:

Alongside the expansion of the automotive components sector, North Macedonia has also revitalized its bus assembly capabilities in recent years. The entry of a major European OEM, the Belgian manufacturer Van Hool, has strengthened the country’s position in the industry.

North Macedonia offers a highly cost-competitive operating environment for automotive component manufacturing. The labor force is well-educated, flexible, and possesses a strong work ethic.

The country ensures a sustainable supply of young, highly skilled labor at competitive costs. Wage levels in the region remain among the most cost-effective in Europe, significantly reducing overall operational expenses for investors.

North Macedonia-based companies have a strong global export reach, supplying markets in Europe, Russia, Turkey, Africa, and beyond. The country benefits from duty-free access to a market of over 680 million customers, facilitated by:

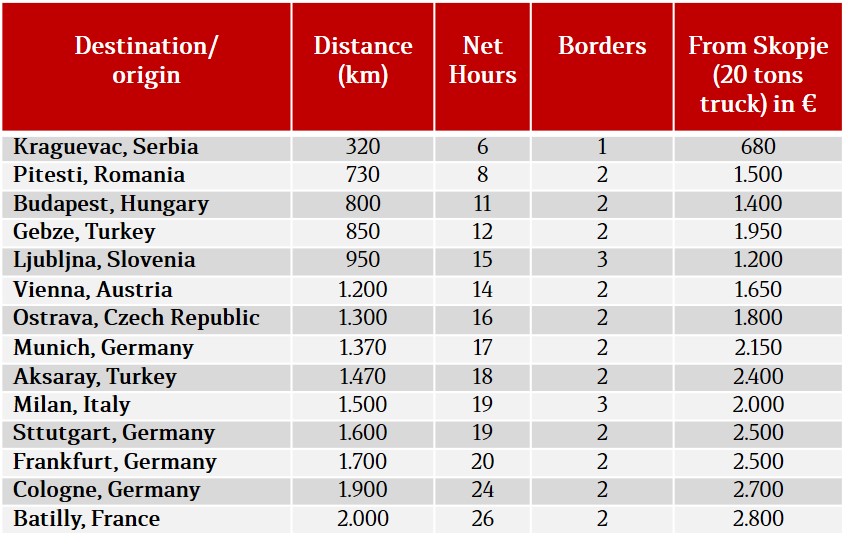

North Macedonia’s strategic location enables rapid delivery to key markets:

Currently, over 50 companies are operating in North Macedonia, covering, among others, OEMs, seat belts and seat belt parts production, buses and coaches, various automotive and machine parts, and railway vehicles and components. Companies such as Johnson Matthey, Kromberg & Schubert, Amphenol Technology, Marquardt, Tab Mak, Joyson Safety Systems, Dräxlmaier, Gentherm, Lear Corporation, Kostal, Adient, ARC Automotive, LTH Learnica, Adient Automotive, Aptiv, ODW Elektrik, Accomplast, Çağatay Kablo, Murat Ticaret, Dura Automotive Systems, and many others have established large export-oriented production facilities in the country, with several having reinvested multiple times.

“I’ve been asked why the company invests in North Macedonia instead of in emerging countries such as India or China. Well, North Macedonia is one of the emerging centers. It has a history of connecting various worlds – the East and the West, and Europe and America nowadays. I’m convinced that this investment will be successful,” said Philip Van Hool, CEO of Van Hool.

“We are seeking qualified and trained personnel, as well as employees for simpler jobs, who want to build and develop our facility together in a technologically sophisticated manufacturing plant. We are confident that we can find these people in North Macedonia and that, together with them, we can open a new chapter in the success story of our company, which has lasted for nearly 90 years,” said Harald Marquardt, CEO of Marquardt Group.